Compressed air used in the manufacturing process of pet food should be considered a Critical Factor as it can have a direct affect on the Commercial Sterility of the final product. Assuring pet food safety and quality is essential for the viability of any pet food manufacturer.

Pet Food Compressed Air & Gas Testing Specifications

Trace Analytics, LLC is an A2LA Accredited Laboratory in compliance with ISO 17025 as required by BRC and SQF. We can test to a wide variety of specifications. Some example specs commonly used in Pet Food are shown at the bottom of the page.

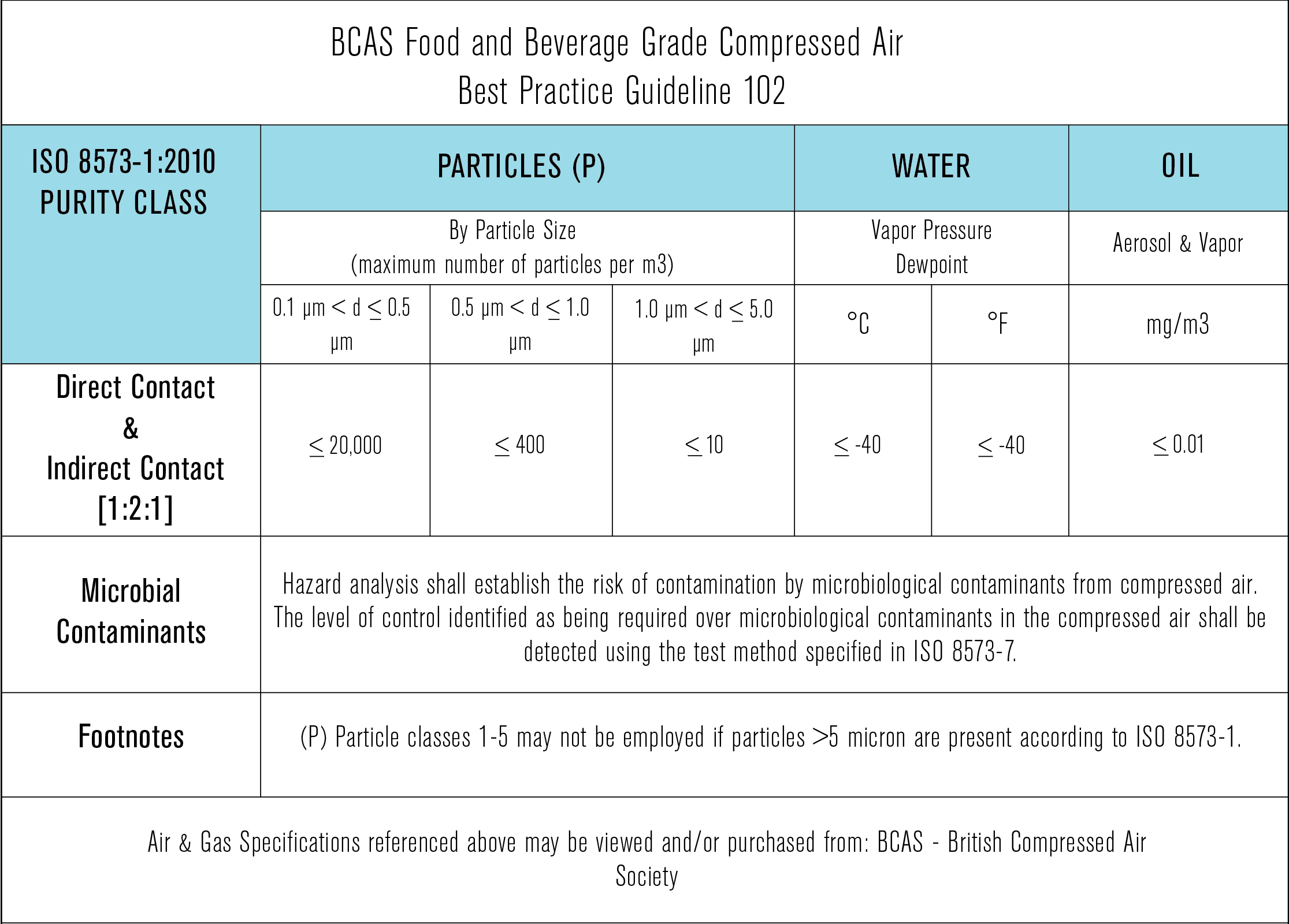

Compressed air quality should be tested and verified and additional testing is warranted whenever maintenance work or any activity that may affect the air quality is performed on the compressed air system. It is suggested that a representative selection of the air outlets shall be tested to confirm that the compressed air meets the relevant Purity Classes noted in the Table above. A periodic air test program can provide critical information to monitor air quality and help prevent contamination of the pet food supply. Due to the critical nature of compressed air used in the pet food manufacturing process, qualified personnel should be employed to properly maintain, service, and test the compressed air system.

| ISO 8573-1:2010 Compressed Air Contaminants and Purity Classes | ||||||||

|---|---|---|---|---|---|---|---|---|

| CLASS | PARTICLES | WATER | OIL | |||||

| By Particle Size (maximum number of particles per m3) See Note 2 |

By Mass | Vapor Pressure Dewpoint | Liquid | Liquid, Aerosol, & Vapor See Note 1 |

||||

| 0.1 µm < d ≤ 0.5 µm | 0.5 µ m< d ≤ 1.0 µm | 1.0 µm < d ≤ 5.0 µm | mg/m3 | °C | °F | g/m3 | mg/m3 | |

| 0 | As specified by the equipment user or supplier and more stringent than class 1 | |||||||

| 1 | ≤ 20,000 | ≤ 400 | ≤ 10 | - | ≤ -70 | ≤ -94 | - | ≤ 0.01 |

| 2 | ≤ 400,000 | ≤ 6,000 | ≤ 100 | - | ≤ -40 | ≤ -40 | - | ≤ 0.1 |

| 3 | - | ≤ 90,000 | ≤ 1,000 | - | ≤ -20 | ≤ - 4 | - | ≤ 1 |

| 4 | - | - | ≤ 10,000 | - | ≤ +3 | ≤ +37 | - | ≤ 5 |

| 5 | - | - | ≤ 100,000 | - | ≤ +7 | ≤ +45 | - | - |

| 6 | - | - | - | 0 – ≤ 5 | ≤ +10 | ≤ +50 | - | - |

| 7 | - | - | - | 5 – ≤ 10 | - | - | ≤ 0.5 | - |

| 8 | - | - | - | - | - | - | ≤ 5 | - |

| 9 | - | - | - | - | - | - | ≤ 10 | - |

| X | - | - | - | > 10 | - | - | > 10 | > 5 |

| MICROBIOLOGICAL CONTAMINANTS | OTHER GASEOUS CONTAMINANTS | |||||||

| No purity classes are identified | No purity classes are identified Gases mentioned are: CO, CO2, SO2, NOX, Hydrocarbons in the range of C1 to C5 |

|||||||

| Note 1: ISO 8573 Oil includes aerosol, vapor in the range of C6+, and liquid oil. Liquid oil is typically sampled when wall flow is present, contamination is suspected, or results are greater than 5 mg/m3. Trace can provide a separate kit for liquid oil testing. Note 2: For Particle Class 0, 1, & 2 (0.1 - 0.5 µ range only), a laser particle counter with a high-pressure diffuser is required. Rental of this equipment is available on a reservation basis. Contact us for details. To qualify for Particle Classes 0 through 5, there can be no particles greater than 5µ present. In some cases, Trace uses alternative sampling techniques or analytical methods to those specified in ISO 8573, for details see Smith White Paper, 2012. |

||||||||

| Air & Gas Specifications referenced above may be viewed and/or purchased from: ANSI - American National Standards Institute |

||||||||