Contact Plate Testing

Contact plate testing is ideal for surfaces that are intended to be free from microorganisms or have strict quality control requirements.

Environmental Testing with Contact Plates

Microorganisms’ pervasive nature enable them to adapt and utilize nutrients available in their surrounding environments. In manufacturing facilities, it is essential to implement processes and systems to prevent microorganisms from contaminating controlled environments. Regular testing and monitoring can help to ensure that your cleaning protocols and sanitation procedures are working effectively and appropriately. Contact plate testing is ideal for surfaces that are intended to be free from microorganisms or have strict control. More specifically known as RODAC (replicate organism detection and counting) plates; they are used for microbiological monitoring of all surfaces. Identifying the presence of microorganisms allow manufacturers to make more stringent hygiene protocols, remediation procedures, and prevent cross-contamination of end-products.

As a 17025:2017 accredited, third-party microbiological testing lab, Trace Analytics is proud to offer contact plate testing for clients to help them meet certification requirements like ISO14698, ISO 14644, ISO 18593, SQF monitoring, and FDA monitoring. We can even work with you to test to your facilities’ custom monitoring plan.

Why Perform Contact Plate Testing

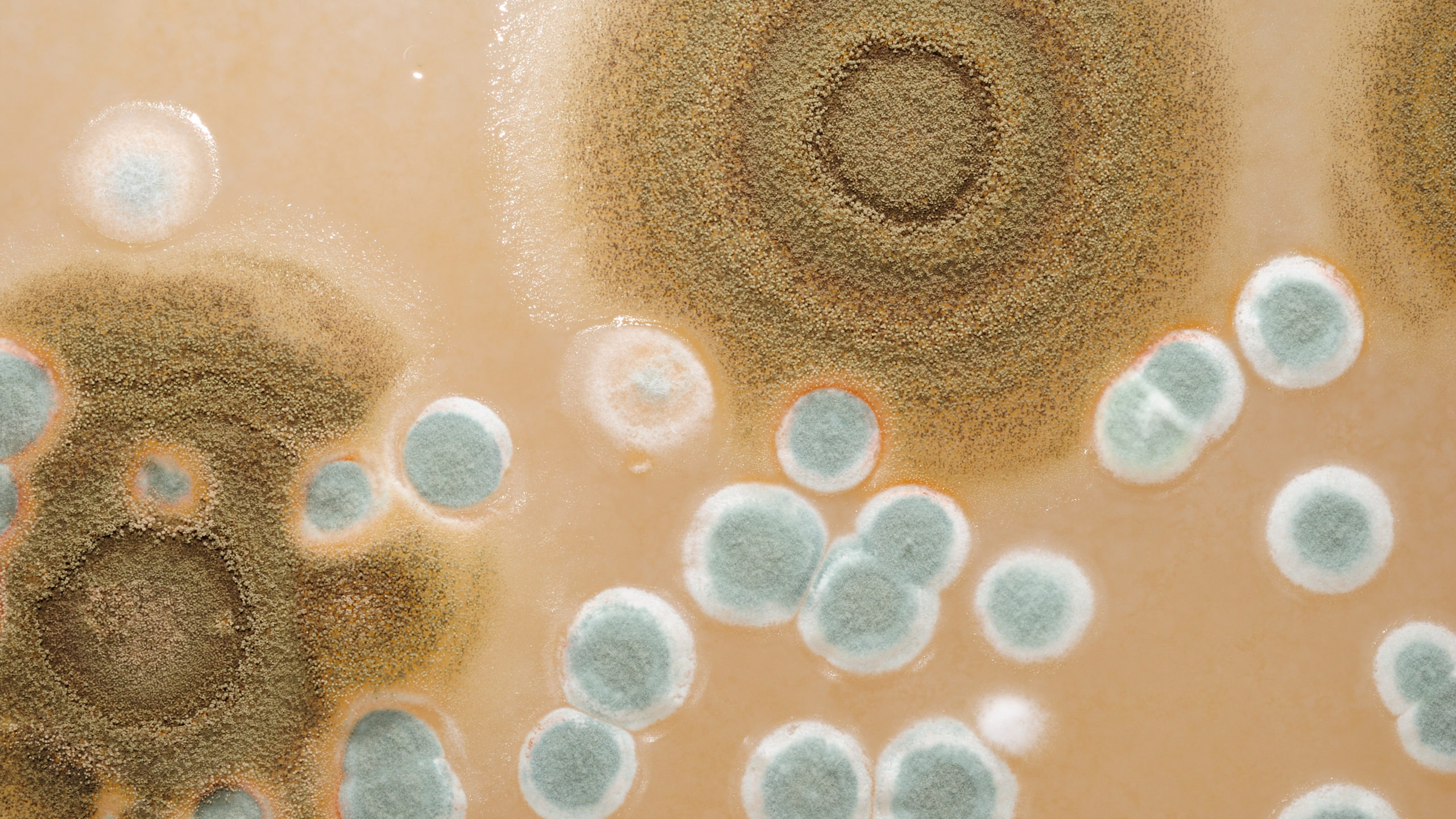

Our triple-bagged, ready to use contact plates can be used for environmental monitoring of surfaces in critical cleanrooms, isolators, and non-critical areas. Contact plates are usually used to assure the cleanliness of the cleanrooms, laboratories, etc.

Manufacturing facilities that implement rigorous cleaning and sanitization procedures need to know they are always working effectively. Regular monitoring and testing for bacteria, yeast, and mold can help isolate areas that need re-training or additional supervision as well as prevent potential shutdowns, recalls, or loss of product. These contact plates are available with various growth media recipes that allow microbes to flourish.

Contact plate testing is ideal for customers who have multiple critical surfaces that need to be free of microorganisms or are monitored in strict control. They are best used on flat, stable surfaces, contact plate testing is effective on work benches, lab garments, and at-risk areas.

What to Test For

Testing Made SimpleAccurateEasy

Trace Analytics’ laboratory is accredited by the American Association for Laboratory Accreditation. We use state-of-the-art lab equipment that allows us to analyze hundreds of compressed air and environmental samples daily. The result is consistency, accuracy, precision, and rapid turnaround. Trace is an A2LA accredited laboratory complying with ISO 17025, certificate #0322-01.