Laser Particle Counters

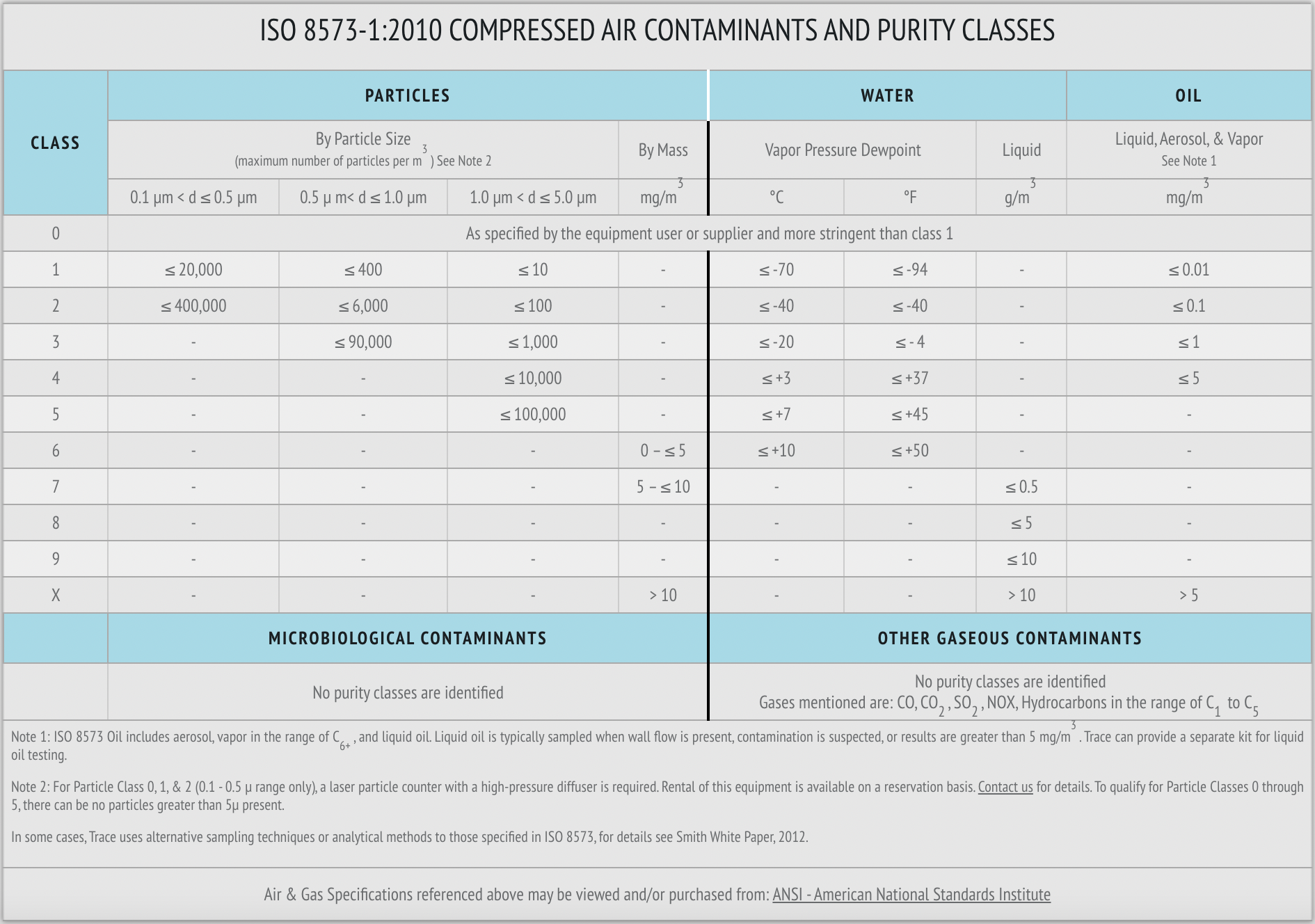

Optical Sizing Instruments for Compressed Air Testing. Laser particle counters allow customers with strict purity classes to test for particles in smaller size ranges. ISO 8573-1 specifies that Classes 1 and 2 require an analysis of the particle size range 0.1 – 0.5 micron.

Particulate Testing in Compressed Air Systems

Airborne particle counters play a crucial role in monitoring, classifying, and diagnosing the source of contaminants in compressed air systems. While a particle counter won’t identify specifically what kinds of dust or particulates are present in the ambient air or compressed air system, a particle counter will identify how many particles of a certain size are present in the compressed air system.

Exhaust, smoke, dirt, air pollutants, microplastics, and rust are all types of compressed air contaminants that can enter the system and interfere with the health of the compressed air system or the safety of the end-product.

Handheld particle counters are a small and portable self-contained device easily transported for use with testing compressed air systems. The Setra LPC can detect and count physical particles as small as 0.3 microns up to 25.0 microns at 0.1CFM flow rate. Handheld systems provide convenience that captures data locally, which is indexed by a built-in display screen or USB connection. The Setra LPC is calibrated with NIST traceable PSL spheres.

Benchtop portable particle counters, like the AeroTrack, are a larger and more sensitive device that allow for particle classification as low as 0.1 micron to 10.0 microns at 1.0 CFM flow rate, featuring larger color touch screen, built-in printer, USB connection and the capacity to run pre-programed standard modes. The 0.1 micron particle counter is calibrated with NIST traceable PSL spheres.

Meeting ISO 8573 Classes 1 and 2

Laser particle counters allow customers with strict purity classes to test for particles in smaller size ranges. ISO 8573-1 specifies that Classes 1 and 2 require an analysis of the particle size range 0.1 – 0.5 microns. Should manufacturers choose to test to these high limits, laser particle counters are available for rental.

Industries We Serve

Why Choose Trace Analytics?

Accredited

Our A2LA accredited laboratory is an unbiased third-party laboratory with no financial interest in other compressed air products. The extensive quality control procedures at Trace’s lab ensures that you will receive quality data. Trace is an A2LA accredited laboratory complying with ISO 17025, certificate #0322-01.

Easy to Use Kits

The AirCheck✓ Kit™ is designed for use with compressed breathing air specifications requiring a dry dew point, such as ISO 8573, NFPA 1989, CGA, ISPE, and more. Other specifications are available. These kits are typically used by food, packaging, medical device, pharmaceutical, nuclear, scuba divers, fire departments and industrial breathing air facilities to test compressed air to meet their requirements.

Satisfaction

Compressed air has been our specialty since 1989 — our AirCheck✓™ Team of Experts has decades of experience in the specific field of compressed air and environmental analyses, testing, and troubleshooting. Excellent customer service, and the desire to provide a more efficient and accurate testing experience, have been the backbone of our company since 1989 — and still hold true today. We pride ourselves on the level of customer service we provide — it is the core of our relationship with all of our customers.

Testing Made SimpleAccurateEasy

Trace Analytics’ laboratory is accredited by the American Association for Laboratory Accreditation. We use state-of-the-art lab equipment that allows us to analyze hundreds of compressed air and environmental samples daily. The result is consistency, accuracy, precision, and rapid turnaround. Trace is an A2LA accredited laboratory complying with ISO 17025, certificate #0322-01.