Compressed Air System

Validations

Validations

New installations, maintenance, or additions to compressed air systems should be validated before use. Compressed air testing is simple with our easy-to-use AirCheck✓Kit™.

Validations and Qualifications for Compressed Air Systems

With any new installation or change to a compressed air system comes the risk of contamination. Contaminated compressed air systems can put products and end-users at risk if left unchecked. Validations and qualifications should be performed upon completion of the system installation to test the quality of the compressed air or gas and to ensure no contaminants are left in the distribution system.

Trace Analytics can help your team with timelines, sampling, training, documentation, and troubleshooting. Contact our team of experts to learn more about compressed air validations.

Compressed Air Validation FAQs

Planning a Compressed Air Validation

Risk Assessment

Compressed air risk assessments are a great way to prepare for your validation. Understanding the qualities and limitations of the compressed air system, the environment of the system, and the point of use materials can help users determine appropriate purity classes and testing parameters.

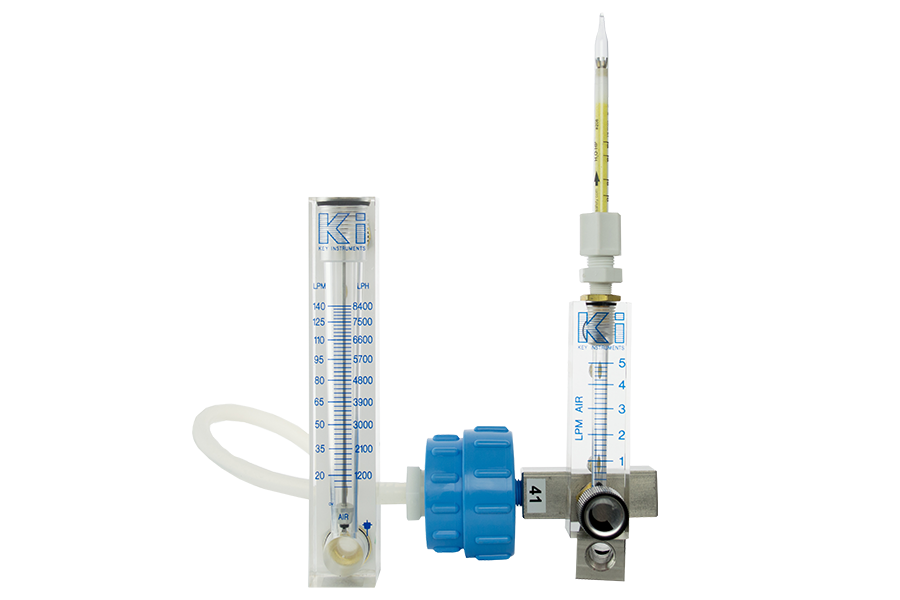

Sampling Set Up

The first step toward ensuring accurate results is understanding your sampling point set up. Use this sampling point handout to ensure that your test results are reporting contamination only from your compressed air system and are not reflective of poor sampling technique or a contaminated testing kit.

Documents and Training

It is critical to retain documentation for your testing from calibration documents, to the final results. Trace Analytics can provide email copies of the necessary documentation.

Trace Analytics provide training for all our test kits with downloadable certificates of completion for your records.

K810 AirCheck Kit for Manufacturing

The AirCheck✓ Kit™ K810 is designed for use with manufacturing specifications such as ISO 8573, and other custom specifications testing for particles, water, and total oil. This kit is typically used by food manufacturers, pharmaceutical manufacturers, medical device facilities, and nuclear plants who use low pressure air in their processes and systems. Test from the compressor or point of use. Watch our online sampling video for kit instructions.

Testing Made SimpleAccurateEasy

Trace Analytics’ laboratory is accredited by the American Association for Laboratory Accreditation. We use state-of-the-art lab equipment that allows us to analyze hundreds of compressed air and environmental samples daily. The result is consistency, accuracy, precision, and rapid turnaround. Trace is an A2LA accredited laboratory complying with ISO 17025, certificate #0322-01.

Ready to Learn More?

Testing Services for Manufacturers

TOLL FREE

1.800.247.1024

LOCAL LINE

512.263.0000

OFFICE HOURS (CT)