Instrument Air Quality

Nuclear Power Production and Pneumatic Instrument Use. To ensure clean, dry, air, perform regular nuclear compressed air testing with Trace Analytics.

Compressed Air Testing in Nuclear Power Production

The quality standard for instrument air is ANSI/ISA-S7.0.01-1996. The American National Standards Institute’s (ANSI) Instrument Society of America (ISA) recognizes the importance of clean dry air (CDA) and the role it plays in running pneumatic controllers and pneumatic instruments. Instrument air that is not clean and dry can have devastating effects on the instruments it controls resulting in system inaccuracies or failures.

ANSI/ISA-S7.0.01-1996 addresses 4 elements of instrument air quality; dew point, particle size, lubricant, and contaminants. The compression process dramatically increases condensation and contaminants in the air once it is compressed. Learn more about Compressor Contamination here.

Industry Wide Standards

In order to ensure safety and improve nuclear power plants’ efficient production of electricity, instrument air systems require regulation, improvement, and monitoring. In 2014, the nuclear industry came together to make improvements to compressed air quality, efficiency, and safety. The Nuclear Regulatory Commission (NRC) and the Institute of Nuclear Power Operations (INPO) issued regulations; the Electric Power Research Institute (EPRI) set maintenance standards; and the Compressed Air Nuclear Users Group (CANUG) improved air system design.

At Trace Analytics, our team of experts is dedicated to providing safe, clean air at the highest quality standards.

| ANSI / ISA—S7.0.01-1996 | |||

|---|---|---|---|

| PARTICLES | WATER | LUBRICANT CONTENT | |

| By Particle Size maximum number of particles per m3 |

Vapor Pressure Dewpoint | ||

| >40 µm | °C | °F | ppm |

| NONE | < 4 | < 39 | ≤ 1 |

| A maximum 40 micron particle size in the instrument air system is acceptable for the majority of pnuematic devices. Pneumatic devices that require less than 40 micron particle size shall have additional filtration. | Pressure dew point at the dryer outlet shall be at least 10°C (18°F) below the minimum temperature to which any part of the instrument air system is exposed. It shall not exceed 4°C (39°F) at line pressure. | Should be as close to zero as possible, and under no circumstance shall it exceed 1 ppm. | |

| For Nuclear industry - INPO requirements include ensuring that air testing and sampling methods are performed in accordance with the most current ISO-8573 for solid particle content (particulates), humidity (dew point), oil aerosol content, and oil vapor and organic solvent content. At the optical microscope magnification used to determine compliance, the entire filter is scanned with 5 µm being the minimum particle size determined. If no particles are detected, a <5 µm value is entered. Contact Trace for details. |

|||

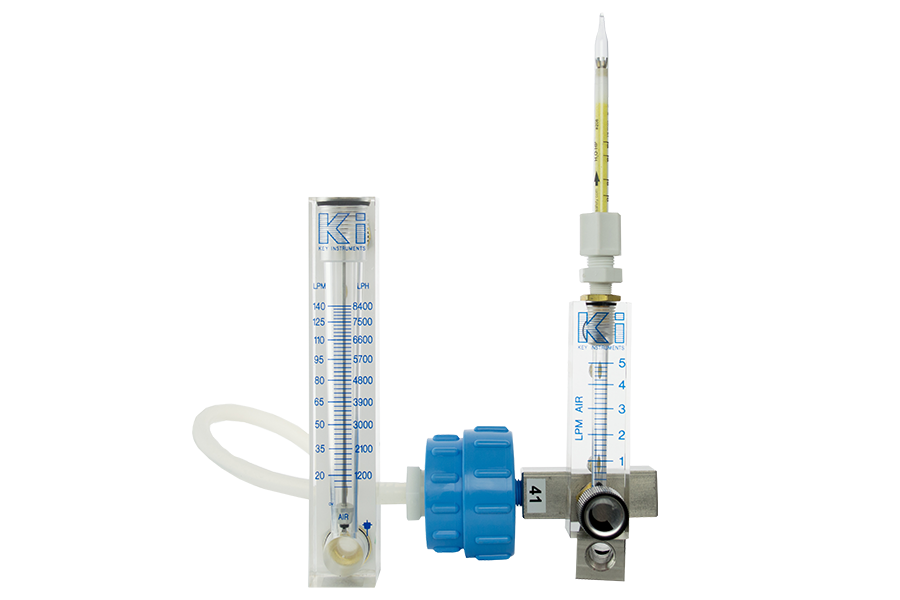

AirCheck Kits Available

K810 AirCheck Kit for Manufacturing

The AirCheck✓ Kit™ K810 is designed for use with manufacturing specifications such as ISO 8573, and other custom specifications testing for particles, water, and total oil. This kit is typically used by food manufacturers, pharmaceutical manufacturers, medical device facilities, and nuclear plants who use low pressure air in their processes and systems. Test from the compressor or point of use. Watch our online sampling video for kit instructions.

Why Choose Trace Analytics?

Online Tools and Reports

Access reports, sampling instructions, troubleshooting tips, and more all through the Trace Analytics website and AirCheck Academy. Download training documents for your records

View the status of your report, download current and past files, and manage who receives notifications in one portal.

Test with the Experts

Our A2LA accredited laboratory specializes in compressed air and gas testing, and our experts have participated in educational endeavors to improve pneumatic tools and instrument air quality safety by attending and speaking at the Air-Operated Valve Users’ Group (AOVUS Group) Conference and Compressed Air Nuclear Users Group (CANUG) Meetings.

Other Testing Services for Manufacturers

Testing Made SimpleAccurateEasy

Trace Analytics’ laboratory is accredited by the American Association for Laboratory Accreditation. We use state-of-the-art lab equipment that allows us to analyze hundreds of compressed air and environmental samples daily. The result is consistency, accuracy, precision, and rapid turnaround. Trace is an A2LA accredited laboratory complying with ISO 17025, certificate #0322-01.