Pharmaceutical Process Air & Gas Testing

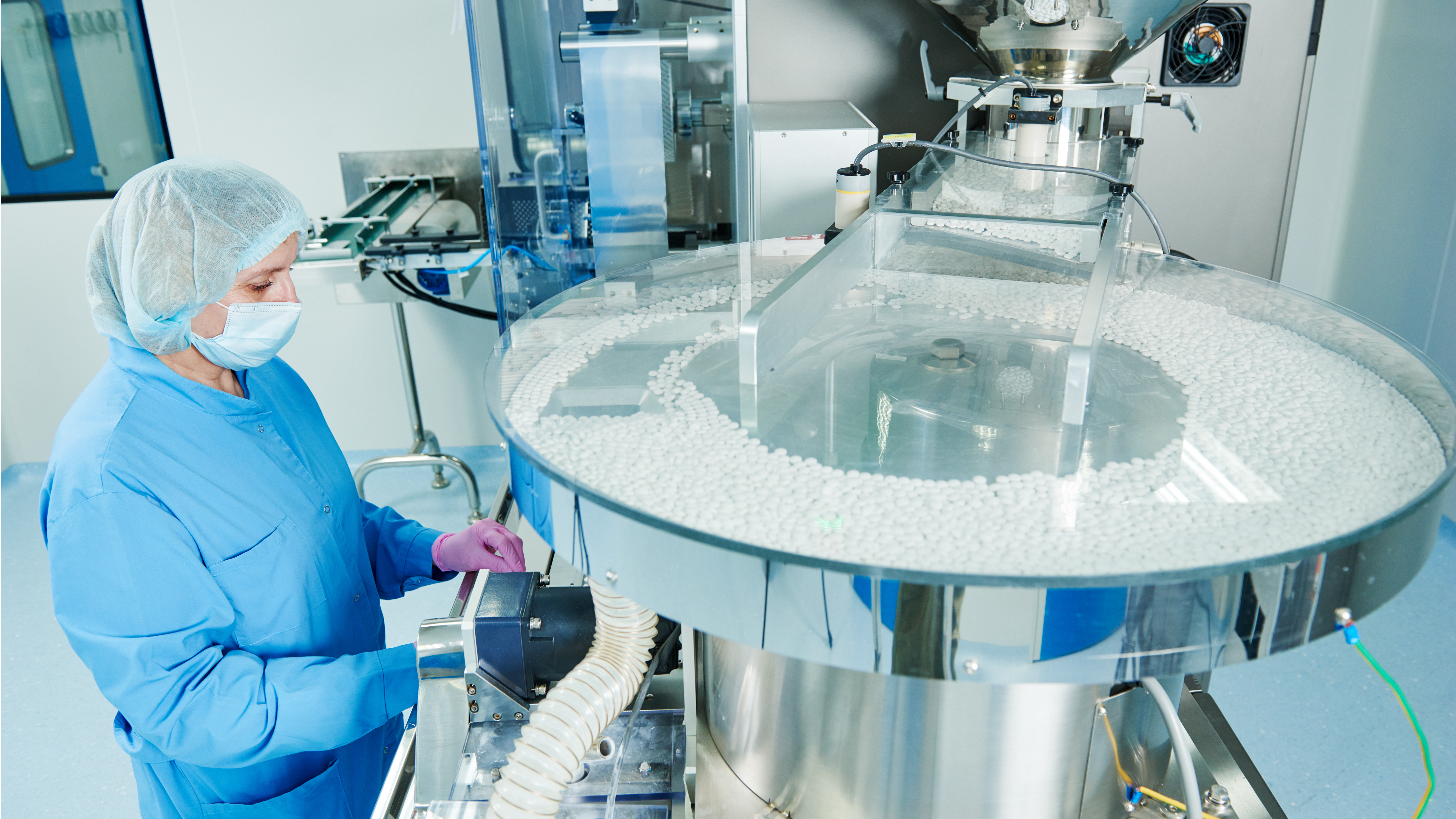

Compressed air is a critical utility used widely throughout pharmaceutical manufacturing processes and it is used both directly and indirectly with pharmaceutical products. Pharmaceutical process air testing with Trace Analytics is easy and straightforward.

Pharmaceutical Manufacturing Process Air Testing

Regular testing of compressed air systems and other process gases that come into contact with pharmaceutical products is critical to ensuring the quality and integrity of the product.

At Trace Analytics, our team of experts is dedicated to providing safe, clean air at the highest quality standards while simultaneously offering guidance for pharmaceutical manufacturers when there is not clear testing criterion.

In the absence of a specified standard, pharmaceutical manufacturers are recommended to rely on the International Organization for Standardization (ISO) 8573-1:2010 air standards in addition to a regular air testing schedule to maintain the appropriate air purities. The ISO 8573 Purity Class chosen by a manufacturing facility is dependent upon the individual manufacturer’s use of the compressed air or process gas and its contact with the pharmaceutical product. The facility should begin by performing a Hazard Analysis, which will help the manufacturer identify potential compressed air hazards, assess the existing control measures, and ultimately determine if extra controls are needed.

Pharmaceutical Industry

Compressed Air and Gas Standards

| ISO 8573-1:2010 COMPRESSED AIR CONTAMINANTS AND PURITY CLASSES | ||||||||

|---|---|---|---|---|---|---|---|---|

| CLASS | PARTICLES | WATER | OIL | |||||

| By Particle Size (maximum number of particles per m3) See Note 2 |

By Mass | Vapor Pressure Dewpoint | Liquid | Liquid, Aerosol, & Vapor See Note 1 |

||||

| 0.1 µm < d ≤ 0.5 µm | 0.5 µ m< d ≤ 1.0 µm | 1.0 µm < d ≤ 5.0 µm | mg/m3 | °C | °F | g/m3 | mg/m3 | |

| 0 | As specified by the equipment user or supplier and more stringent than class 1 | |||||||

| 1 | ≤ 20,000 | ≤ 400 | ≤ 10 | - | ≤ -70 | ≤ -94 | - | ≤ 0.01 |

| 2 | ≤ 400,000 | ≤ 6,000 | ≤ 100 | - | ≤ -40 | ≤ -40 | - | ≤ 0.1 |

| 3 | - | ≤ 90,000 | ≤ 1,000 | - | ≤ -20 | ≤ - 4 | - | ≤ 1 |

| 4 | - | - | ≤ 10,000 | - | ≤ +3 | ≤ +37 | - | ≤ 5 |

| 5 | - | - | ≤ 100,000 | - | ≤ +7 | ≤ +45 | - | - |

| 6 | - | - | - | 0 – ≤ 5 | ≤ +10 | ≤ +50 | - | - |

| 7 | - | - | - | 5 – ≤ 10 | - | - | ≤ 0.5 | - |

| 8 | - | - | - | - | - | - | ≤ 5 | - |

| 9 | - | - | - | - | - | - | ≤ 10 | - |

| X | - | - | - | > 10 | - | - | > 10 | > 5 |

| MICROBIOLOGICAL CONTAMINANTS | OTHER GASEOUS CONTAMINANTS | |||||||

| No purity classes are identified | No purity classes are identified Gases mentioned are: CO, CO2, SO2, NOX, Hydrocarbons in the range of C1 to C5 |

|||||||

| Note 1: ISO 8573 Oil includes aerosol, vapor in the range of C6+, and liquid oil. Liquid oil is typically sampled when wall flow is present, contamination is suspected, or results are greater than 5 mg/m3. Trace can provide a separate kit for liquid oil testing. Note 2: For Particle Class 0, 1, & 2 (0.1 - 0.5 µ range only), a laser particle counter with a high-pressure diffuser is required. Rental of this equipment is available on a reservation basis. Contact us for details. To qualify for Particle Classes 0 through 5, there can be no particles greater than 5µ present. In some cases, Trace uses alternative sampling techniques or analytical methods to those specified in ISO 8573, for details see Smith White Paper, 2012. |

||||||||

| Air & Gas Specifications referenced above may be viewed and/or purchased from: ANSI - American National Standards Institute |

||||||||

| 2011 ISPE GOOD PRACTICE GUIDE - PROCESS GASES, TABLE 7.1 | |||||||

|---|---|---|---|---|---|---|---|

| PARTICLES | WATER | OIL | |||||

| By Particle Size (maximum number of particles per m3) |

By Mass | Aerosols or Vapor Pressure Dewpoint | Liquid | Hydrocarbons | |||

| 0.10 µm < d ≤ 0.5 µm | 0.5 µm < d ≤ 1.0 µm | 1.0 µm < d ≤ 5.0 µm | mg/m3 | °C | °F | g/m3 | mg/m3 |

| Viable and Non-Viable Count Typically equal to the at rest condition of the area served | ≤ -40 | ≤ -40 | - | ≤ 0.5 | |||

| MICROBIAL COUNT | OTHER CHEMICAL IMPURITIES | ||||||

| Non-Sterile Applications | Sterile Applications | (Only as Applicable) Based on the generation technology and/or USP/EU Monograph | |||||

| Guideline limits to be established based on product bioburden limits. Typical level NMT 5 cfu/m3 | As per viable particle requirements for Grade area where the product is exposed to the compressed gas (e.g., Grade A, Grade A/B, Grade B or Grade C) | GAS PURITY | |||||

| Applicable for inert gases such as Nitrogen, as per USP/EU Monograph | |||||||

| Air & Gas Specifications referenced above may be viewed and/or purchased from: ISPE - International Society of Pharmaceutical Engineering |

|||||||

| CLEANROOM CLASSIFICATIONS A | ||||

|---|---|---|---|---|

| CLEAN AREA CLASSIFICATION (0.5 ΜM PARTICLES/FT3) |

ISO DESIGNATION B | ≥0.5 ΜM PARTICLES/M3 | MICROBIOLOGICAL ACTIVE AIR ACTION LEVELS C (CFU/M3) |

MICROBIOLOGICAL SETTLING PLATES ACTION LEVELSC,D (DIAM 90MM; CFU/4 HOURS) |

| 100 | 5 | 3,520 | 1 e | 1 e |

| 1,000 | 6 | 35,200 | 7 | 3 |

| 10,000 | 7 | 352,000 | 10 | 5 |

| 100,000 | 8 | 3,520,000 | 100 | 50 |

| All classifications based on data measured in the vicinity of exposed materials/articles during periods of activity. ISO 14644-1 designations provide uniform particle concentration values for cleanrooms in multiple industries. An ISO 5 particle concentration is equal to Class 100 and approximately equals EU Grade A. Values represent recommended levels of environmental quality. You may find it appropriate to establish alternate microbiological action levels due to the nature of the operation or method of analysis. The additional use of settling plates is optional. Samples from Class 100 (ISO 5) environments should normally yield no microbiological contaminants. |

||||

| RECOMMENDED LIMITS FOR MICROBIAL CONTAMINATION A | ||||

| GRADE | AIR SAMPLE CFU/M3 | SETTLE PLATES (DIAMETER 90MM) CFU/4 HOURS B |

CONTACT PLATES (DIAMETER 55MM) CFU/PLATE |

GLOVE PRINT 5 FINGERS CFU/GLOVE |

| A | < 1 | < 1 | < 1 | < 1 |

| B | 10 | 5 | 5 | 5 |

| C | 100 | 50 | 25 | - |

| D | 200 | 100 | 50 | - |

| These are average values. Individual settle plates may be exposed for less than 4 hours. |

||||

| Air & Gas Specifications referenced above may be viewed and/or purchased from: ANSI - American National Standards Institute |

||||

AirCheck Kits Available

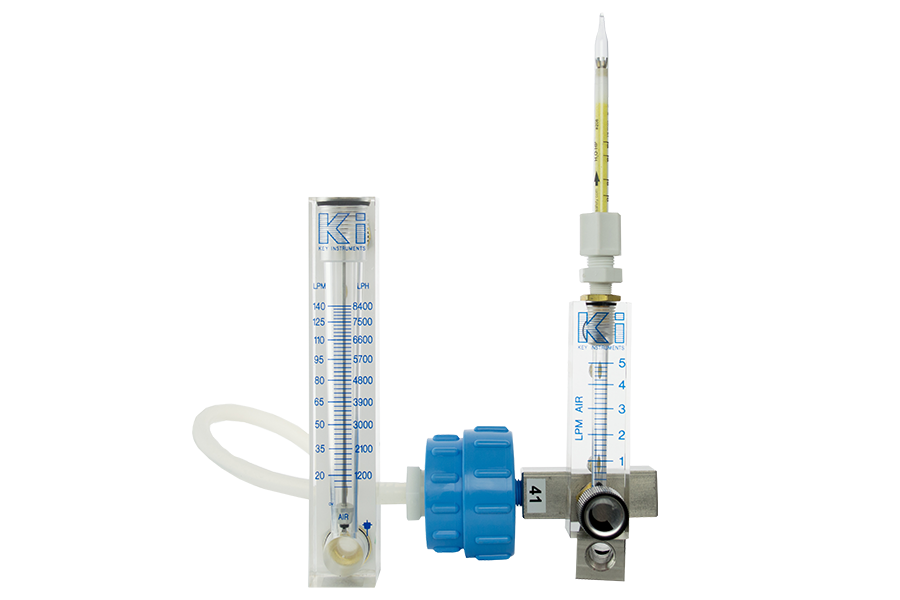

K810 AirCheck Kit for Pharmaceutical Process Gases

The AirCheck✓ Kit™ K810 is designed for use with manufacturing specifications such as ISO 8573, and other custom specifications testing for particles, water, and total oil. This kit is typically used by food manufacturers, pharmaceutical manufacturers, medical device facilities, and nuclear plants who use low pressure air in their processes and systems. Test from the compressor or point of use. Watch our online sampling video for kit instructions.

Why Choose Trace Analytics?

Meet ISPE Guidelines

The ISPE Good Practice Guide for process gases asserts that compressed air usage in pharmaceutical manufacturing should be free from contaminants and routinely maintained and tested.

Trace Analytics owner and founder, Ruby Ochoa, is a contributor on the ISPE Process Gas Good Practice Guide.

Perform Validations

Trace Analytics has had the pleasure of working on many validation and qualification projects.

Validations of compressed air systems can take many days, require a specified timeline, and can often be complex. Trace can help. make this part of your validation easy and straightforward with quick results.

Test to Custom Specifications

We offer custom testing specifications tailored to meet individual testing needs as well as guidance for manufacturers navigating testing requirements. Our reliable, accurate, and easy-to-use testing kits comply with ISO 8573-1:2010 sampling and analytical requirements, providing assurance to manufacturers about the quality of their final product.

Other Testing Services for Manufacturers

Testing Made SimpleAccurateEasy

Trace Analytics’ laboratory is accredited by the American Association for Laboratory Accreditation. We use state-of-the-art lab equipment that allows us to analyze hundreds of compressed air and environmental samples daily. The result is consistency, accuracy, precision, and rapid turnaround. Trace is an A2LA accredited laboratory complying with ISO 17025, certificate #0322-01.