Kit Upgrades for K201 or Older Models

H20 Testing in Compressed Breathing Air with Trace Analytics

Kit Upgrades Available Now

In efforts to continuously improve, we have upgraded our kits for the simple, easy use of water vapor detector tubes.

Effective January 1, 2021, water vapor results will be determined solely from the water vapor detector tube reading taken at the time of sampling and recorded on the data sheet.

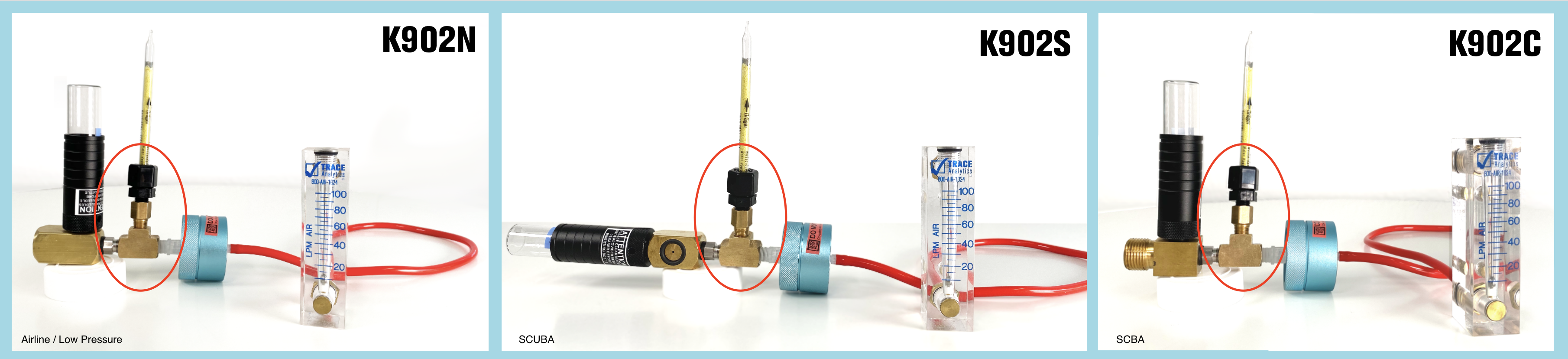

If you would like to continue receiving water vapor results, you will need to upgrade your kit from model K201 to K902.

If you have an older model (LABSm, LABCm, or LABQm), a complete replacement will be provided.

Please fill out the form below to schedule a free kit upgrade.

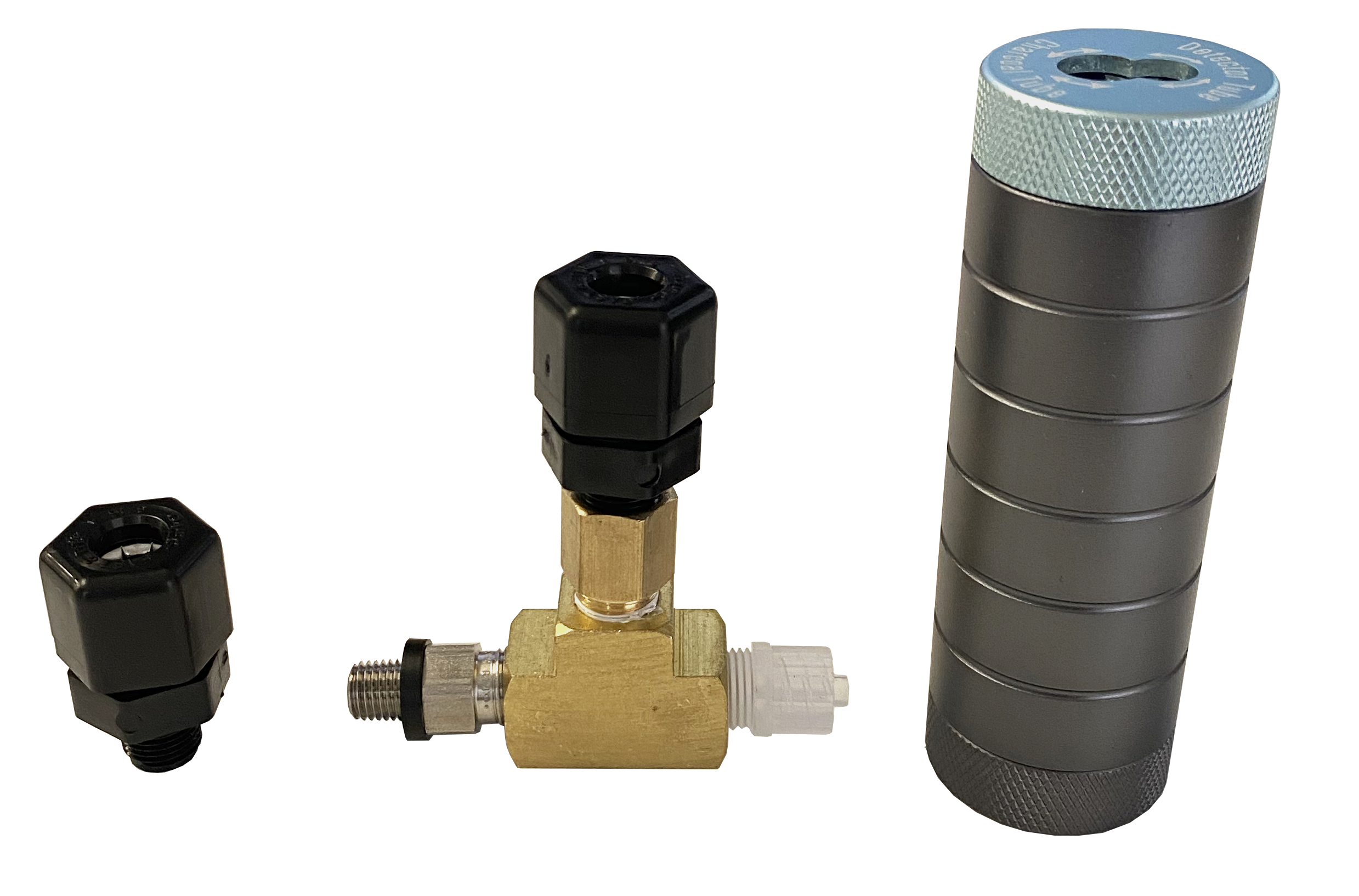

Upgrade Includes

This free upgrade will work with your current K201 kit.

It’s a simple addition that makes sampling easy and straightforward.

Your upgrade will include a brass T, detector tube assembly, filter luer, and stainless steel nipple which will come pre-assembled.

You will also receive a new detector tube tip breaker.

Industries We Serve

Testing Made SimpleAccurateEasy

Trace Analytics’ laboratory is accredited by the American Association for Laboratory Accreditation. We use state-of-the-art lab equipment that allows us to analyze hundreds of compressed air and environmental samples daily. The result is consistency, accuracy, precision, and rapid turnaround. Trace is an A2LA accredited laboratory complying with ISO 17025, certificate #0322-01.

Why Choose Trace Analytics?

Accredited

Our A2LA accredited laboratory is an unbiased third-party laboratory with no financial interest in other compressed air products. The extensive quality control procedures at Trace’s lab ensures that you will receive quality data. Trace is an A2LA accredited laboratory complying with ISO 17025, certificate #0322-01.

Easy to Use Kits

The AirCheck✓ Kit™ is designed for use with compressed breathing air specifications requiring a dry dew point, such as ISO 8573, NFPA 1989, CGA, ISPE, and more. Other specifications are available. These kits are typically used by food, packaging, medical device, pharmaceutical, nuclear, scuba divers, fire departments and industrial breathing air facilities to test compressed air to meet their requirements.

Satisfaction

Compressed air has been our specialty since 1989 — our AirCheck✓™ Team of Experts has decades of experience in the specific field of compressed air and environmental analyses, testing, and troubleshooting. Excellent customer service, and the desire to provide a more efficient and accurate testing experience, have been the backbone of our company since 1989 — and still hold true today. We pride ourselves on the level of customer service we provide — it is the core of our relationship with all of our customers.

TOLL FREE

1.800.247.1024

LOCAL LINE

512.263.0000

OFFICE HOURS (CT)