Excess moisture in a compressed breathing air system can cause significant problems for our customers. The limit for water vapor in most specifications is all about preventing the freezing of the regulator in an SCBA. While water vapor doesn’t hurt the individual, not having air to breathe does! Water contamination can cause corrosion in self-contained breathing apparatus. If compressor filters become saturated, then they are unable to remove carbon monoxide which can be deadly if unaddressed.

Excess moisture is the number one reason most compressed breathing air samples fail. When a sample fails, the compressor needs to be taken out of service, the problem corrected, and a retest must be resubmitted to the laboratory for testing.

We have evaluated a variety of methods for onsite determination of moisture and we have determined that water vapor detector tubes best allow our customers to know immediately if they have a problem with moisture. Detector tubes are an industry standard that provide accuracy, consistency, and ease-of-use for all our customers.

Accuracy of Water Vapor Detector Tubes

Detector tubes have been the industry standard for forty years. NIOSH initiated a detector tube certification program to ensure accuracy and quality of the method in collaboration with the American Industrial Hygiene Association. Water vapor detector tube analytical methods are included in Trace’s ISO 17025 laboratory accreditation.

Draeger states that, at 50L, their 5/a-P tubes have a standard deviation of ±15-20%. Standard deviation is an indication of how far a group of repetitive measurements strays from the average of all the measurements.1

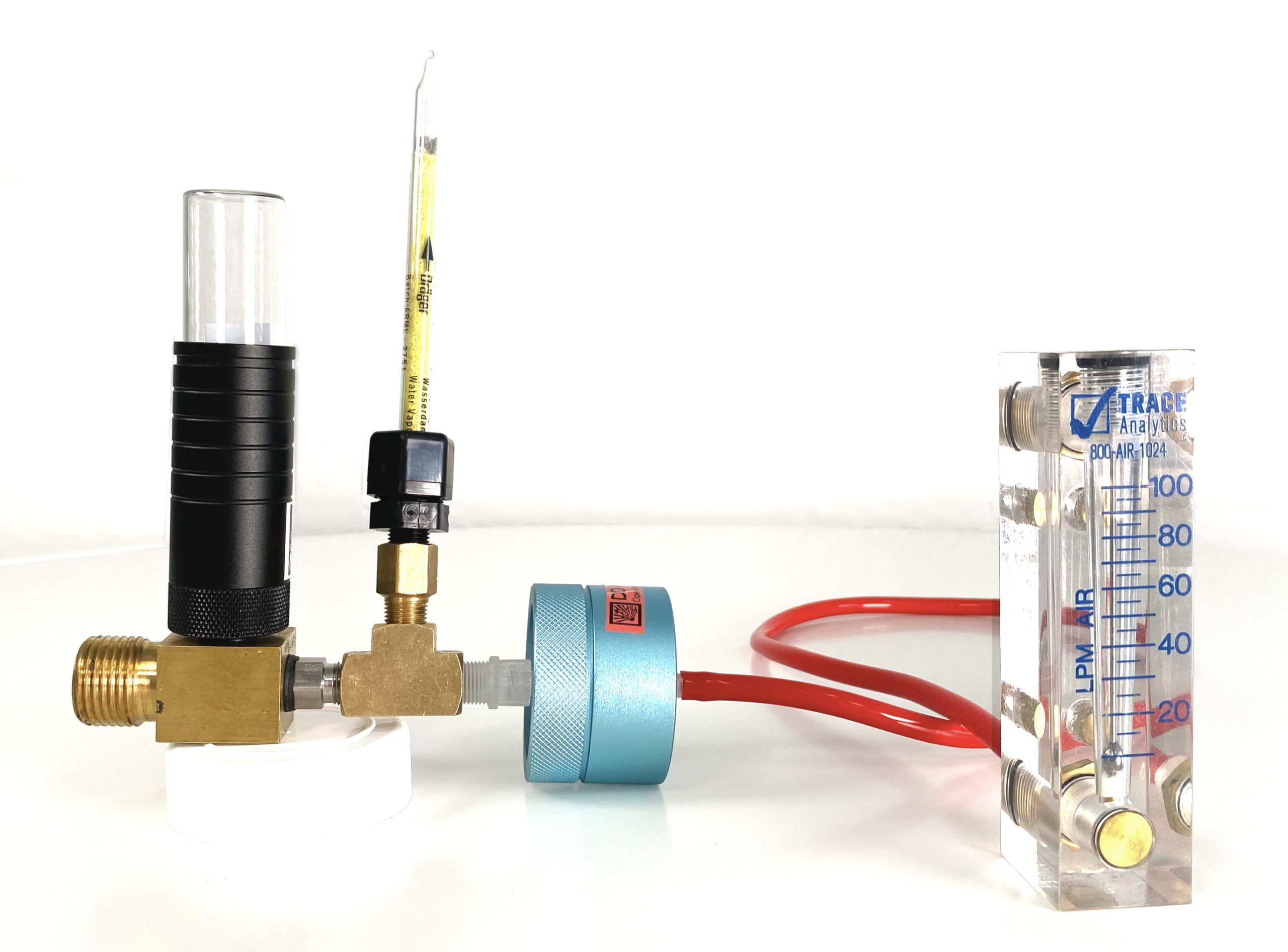

For samples taken at 50 LPM as measured by the provided filter flowmeter for 10 minutes, we have determined the minimum detection limit to be 2.5ppm.

At 24ppm, the tubes have an accuracy of ±6ppm, which is well within the requirements of NFPA 1989 listed under section 6.5.2. This standard requires a minimum detection limit not exceeding 3ppm with an accuracy of +8ppm at 24ppm (NFPA 1989:2019).

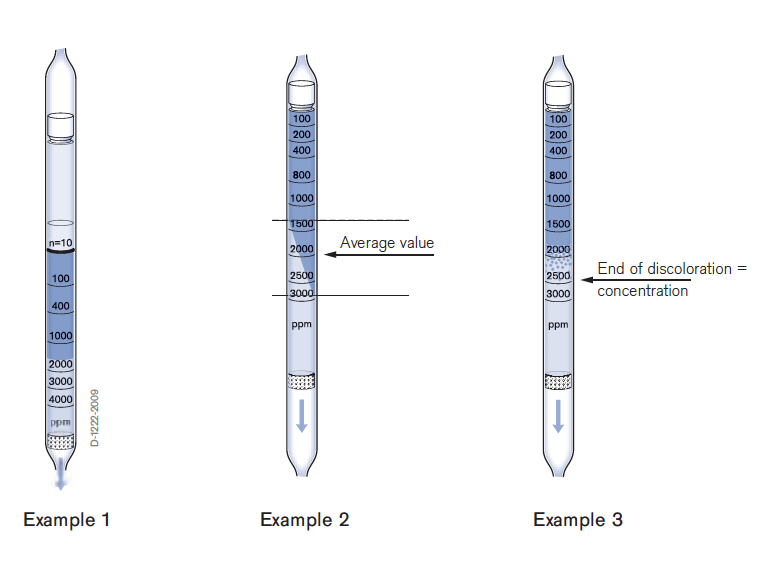

The length of the stain does not correspond to the concentration as a direct measure but is a measure of the mass reaction of the water vapor in the compressed air. Here at Trace Analytics, we have a team of chemists using ISO 17025:2017 accredited methods to convert your water vapor results to parts per million volume (ppmv) and atmospheric dew point (ADP).

Easy to Use – detect moisture in compressed breathing air systems

Water vapor detector tubes are easy-to-use. They do not require extensive equipment knowledge or long sampling times. They fit snugly in our kit and don’t move when air flows through. All of our kits come with a tip breaker to make opening the tubes quick and safe. The marks on the tubes are clear and easy for technicians to read.

Here’s some helpful information about how to read a water vapor detector tube from the OEM, Draeger. If the reddish-brown color change stops in a straight line, you will write down your closest estimation between the nearest two marks on the tube. If the color change is angled, you’ll take the reading exactly in the middle of the angled discoloration. If the color indication is diffused, take the reading from the end of the diffusion. Do not include any grey color change in your reading.

We have a variety of tools to aid customers should they need help at any point in the sampling process. Trace’s partners and clients have access to training videos, instructions, and a staff of fully trained customer service representatives.

Provide Onsite Results

We evaluated a variety of methods for onsite determination of moisture to help our customers reduce the downtime of their compressed air systems. We have determined that the use of detector tubes allows customers to immediately know if they have a problem. They can take corrective action, resample, and then send in both samples to the lab for analysis.

If you determine the sample will not meet your specification limits, you can use the Troubleshooting Tips and take action to correct the problem immediately. Then, take a free retest to confirm that the problem has been fixed. For many of Trace’s customers, being unable to safely fill cylinders for any length of time is problematic.

For our distributors, this means that they resolve the issue in one trip instead of two. Their customers will be better served and experience no downtime due to a failing sample for excess moisture content. A reference table is included with each sample so that the technician can readily determine water results onsite.

Serving Our Customers

We have clients all across the world, from urban centers to rural and remote locations. Detector tubes are easy to ship, provide immediate on-site results, and are easy for a layperson to read in the field, wherever that may be.

Our AirCheck Kits are designed to work with detector tubes. The tubes react when air flows through them. They are not impacted by ambient air conditions. In fact, even on a rainy day at high humidity levels (78%), it takes hours for the ambient air to impact the tubes at all. Our lab only uses the detector tube reading recorded on the datasheet immediately after sampling. Any additional color change during return shipment will not change the results determined onsite.

Our customers all around the world can easily work with, and transport these tubes. While there are other, more high-tech options available, detector tubes are cost-effective, keep sampling times short, and allow us to serve customers in all locations.

If you have any further questions about detector tubes, you are more than welcome to reach out to our exceptional customer service team at any time. Thank you for choosing Trace Analytics.