OSHA & Industrial Breathing Air Testing

OSHA breathing air quality standards need to be met for any industry using compressed air, for the safety of the employees. The AirCheck✓Kit™ helps you comply with the 1st item of OSHA’s 14-point Checklist for Breathing Air Quality and Use.

OSHA Breathing Air Testing

Employers can determine testing schedules based on usage or other workplace factors. Breathing air testing can be performed annually, quarterly, or as necessary to reflect changes in workplace conditions. Maintenance such as filter changes, line additions, or part replacements are examples of times that testing should be performed to ensure the safety of the breathing air per OSHA requirements.

The OSHA Respiratory Protection Standard states that employers shall ensure that cylinders used to supply breathing air to respirators have a certificate of analysis showing the air meets Grade D requirements.

Easy Compliance with the #1 Item on OSHA’s Checklist

Compressed air is used in a variety of industries including welding, sandblasting, spray painting, chemical spill cleaning and more. Some examples of when to use compressed breathing air may include:

- If your employees work in situations where the level of oxygen is insufficient, or potentially insufficient.

- If your employees are potentially exposed to harmful levels of hazardous gases or vapors.

- If your employees are exposed to other potential respiratory hazards, such as dust, mists, fumes, sprays, and other airborne particles.

The 14-point Checklist and other useful OSHA documents are available in our Standards & Specifications section.

Since every customer has unique compressed air testing requirements, we will work with you to package an AirCheck✓Kit™ to meet your specific needs.

| SCBA USE - SELECTED AIR QUALITY SPECIFICATIONS | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| AIR QUALITY SPECIFICATION | THC | CO | CH4 | CO2 | H2O | DP, °F | O2 | N2 | OIL | ODOR |

| CGA Grade D (G-7.1-2011) | N/A | 10 | N/A | 1000 | 67 | -50 | 19.5-23.5 | N/A | 5 | None/Slight |

| CGA Grade L (G-7.1-2011) (SCBA) | N/A | 10 | N/A | 1000 | 24 | -65 | 19.5-23.5 | N/A | 5 | None/Slight |

| NFPA 1989-2013 (N) | 25 (T) | 5 | N/A | 1000 | 24 | -65 | 19.5-23.5 | 75.0-81.0 | 2 | Not Pronounced |

| OSHA 1910.134 Respiratory Protection - 2004 Cylinder (Y) | N/A | 10 | N/A | 1000 | 67 | -50 | 19.5-23.5 | N/A | 5 | None/Slight |

| OSHA 1910.134 Respiratory Protection - 2004 SCBA (S) | N/A | 10 | N/A | 1000 | 67 | -50 | 19.5-23.5 | N/A | 5 | None/Slight |

| THC = Total Gaseous Hydrocarbons, ppmv CO2 = Carbon Dioxide, ppmv O2 = Oxygen, volume % HS = Halogenated Solvents, ppmv CO = Carbon Monoxide, ppmv H2O = Water, ppmv N2 = Nitrogen, volume % Odor = Odor as supplied by customer CH4 = Methane, ppmv DP = Dew Point, °F at 0 psig Oil = Oil Mist & Particulate, mg/m3 |

||||||||||

| Air & Gas Specifications referenced above may be viewed and/or purchased from: CGA - Compressed Gas Association • NFPA - National Fire Protection Association • OSHA - Occupational Health & Safety Administration |

||||||||||

| AIRLINE RESPIRATORS - SELECTED AIR QUALITY SPECIFICATIONS | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AIR QUALITY SPECIFICATION | THC | CO | CH4 | CO2 | H2O | DP, °F | O2 | N2 | OIL | ODOR | OTHER | |

| CGA G-7-2011 Grade D (1) | N/A | 10 | N/A | 1000 | N/A | N/A | 19.5-23.5 | N/A | 5 | None/Slight | N/A | |

| CGA G-7-2011 Grade D (2) | N/A | 10 | N/A | 1000 | N/A | N/A | 19.5-23.5 | N/A | 5 | None/Slight | N/A | |

| CGA G-7.1-2011 Grades D & E (2) | 25 | 10 | N/A | 1000 | N/A | N/A | 20-22 | N/A | 5 | None/Slight | N/A | |

| CSA Z180.1-2013 (<15 psig)(N) | N/A | 5 | 10 | 600 | N/A | N/A | 20-22 | N/A | 1 | None/Slight | Halogenated Hydrocarbons, ppmv | |

| 5 | ||||||||||||

| CSA Z180.1-2013 (15-2216 psig)(L) | N/A | 5 | 10 | 600 | N/A | N/A | 20-22 | N/A | 1 | None/Slight | Halogenated Hydrocarbons, ppmv | Pressure Dewpoint, °C |

| 5 | Subtract 5°C from Lowest Temp; Use -5°C as Default | |||||||||||

| OSHA 1910.134 Respiratory Protection-2004 Compressor (O) | N/A | 10 | N/A | 1000 | (O) | (O) | 19.5-23.5 | N/A | 5 | None/Slight | N/A | |

| THC = Total Gaseous Hydrocarbons, ppmv CO2 = Carbon Dioxide, ppmv O2 = Oxygen, volume % HS = Halogenated Solvents, ppmv CO = Carbon Monoxide, ppmv H2O = Water, ppmv N2 = Nitrogen, volume % Odor = Odor as supplied by customer CH4 = Methane, ppmv DP = Dew Point, °F at 0 psig Oil = Oil Mist & Particulate, mg/m3 |

||||||||||||

| Air & Gas Specifications referenced above may be viewed and/or purchased from: CGA - Compressed Gas Association • CSA - Canadian Standards Association • OSHA - Occupational Health & Safety Administration |

||||||||||||

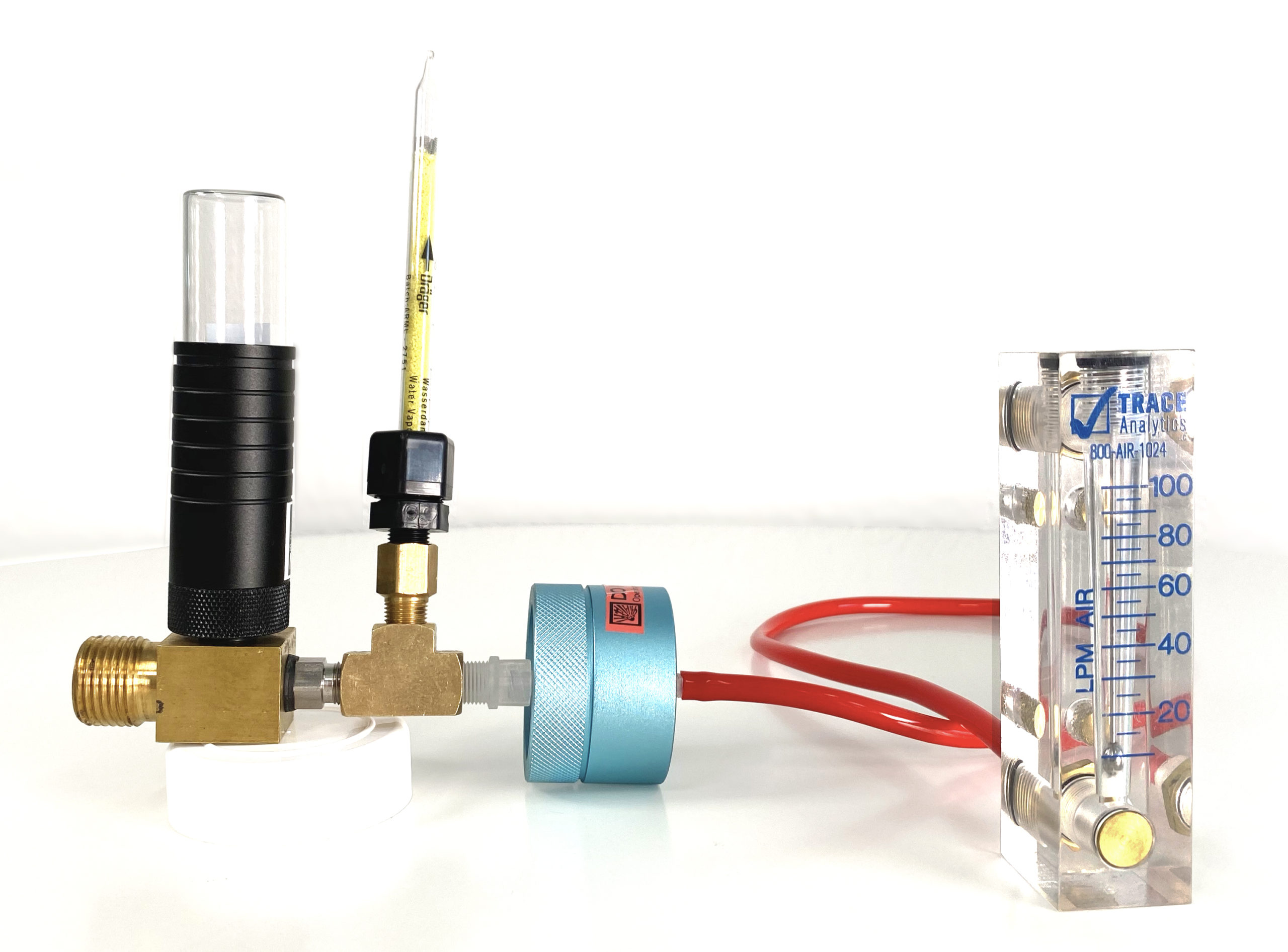

K902 Breathing Air Kit

The AirCheck✓ Kit™ K902 is designed for use with breathing air specifications requiring a dry dew point, such as NFPA 1989, OSHA 1910.134 (Cylinder or SCBA), CGA Grade D (0), and CGA Grade L. Other specifications are available at an additional cost. This kit is typically used by fire service, industrial fire brigades, some dive facilities who use high pressure breathing air to fill SCBAs or any compressor with a desiccant dryer. Test from the compressor or cascade. Watch our online sampling video for Breathing Air Testing.

Other Breathing Air Testing Services

We test to many Compressed Air & Gas Specifications in a variety of industries. Trace has members on the NFPA Committee and we have been a preferred PADI vendor since 1995.

Testing Made SimpleAccurateEasy

Trace Analytics’ laboratory is accredited by the American Association for Laboratory Accreditation. We use state-of-the-art lab equipment that allows us to analyze hundreds of compressed air and environmental samples daily. The result is consistency, accuracy, precision, and rapid turnaround. Trace is an A2LA accredited laboratory complying with ISO 17025, certificate #0322-01.