Compressed air plays a critical role in countless industrial and manufacturing processes, yet its potential for contamination, particularly from hydrocarbons, is often overlooked. While particulate, water, and microbial contamination may be more intuitive to foresee, hydrocarbon contamination is just as critical. Testing for this type of contamination can reveal underlying problems with a compressed air system. Hydrocarbons, which are organic compounds composed solely of hydrogen and carbon atoms, can infiltrate compressed air systems in a variety of ways. Identifying and quantifying these compounds isn’t just a matter of routine testing, it’s a proactive step toward safeguarding product integrity, protecting human health, and maintaining efficient system operations.

Meeting and going beyond ISO Standards

The ISO 8573-1 standard provides clear classifications for compressed air purity including limits for oil aerosols and oil vapors. To meet the stringent requirements of Class 1 and 2 air, it’s critical to quantify oil vapor levels using reliable and accredited testing methods.

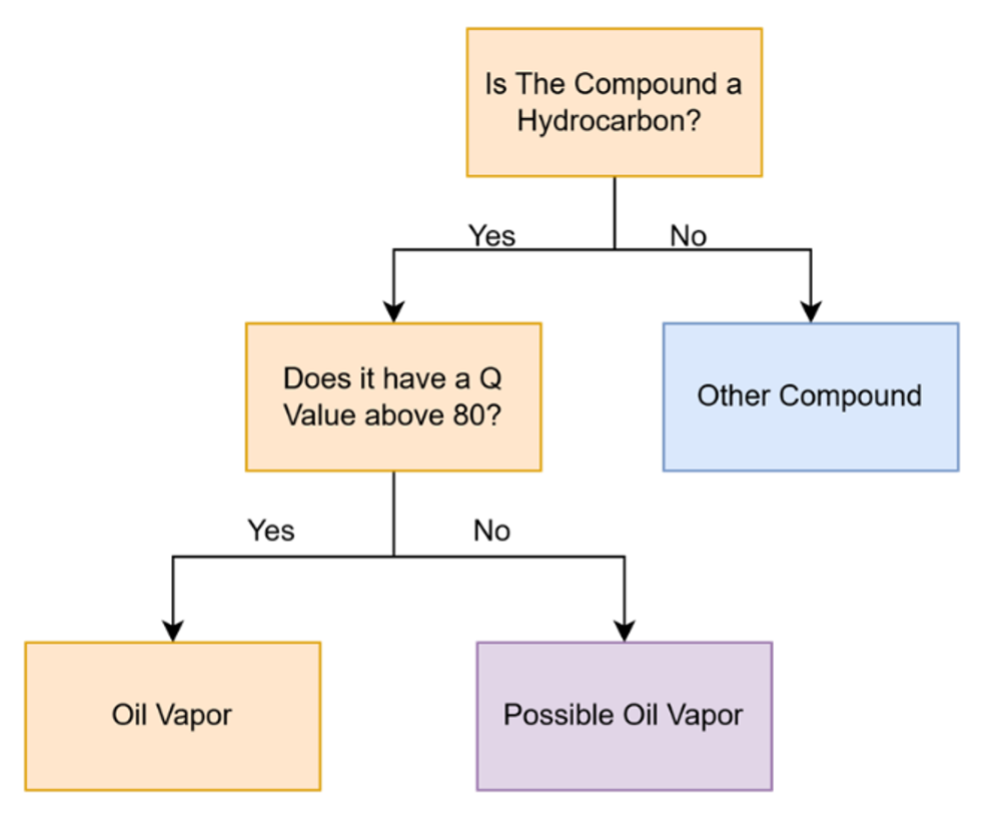

Oil vapors are defined by ISO as hydrocarbons with six or more carbon atoms. Trace Analytics testing distinguishes between verified oil vapors (O1) and other organic compounds (O4), helping facilities understand not only whether their air is compliant but why it may not be.

What is a Q or Qual Value?

Our Q or Qual Value is a number 0 to 100 to indicate how well the compound identified matches NIST (National Institute of Standards and Technology) reference spectra. If the Q value is 80-100, and a hydrocarbon, Trace Analytics will classify the compound as an Oil Vapor and will add it to the Oil Vapor and Total Oil result.

Even though oil vapor results are not required for classes 3 through X, there is still significant benefit in testing for them. Hydrocarbons can still be present at harmful or system-altering levels even when not regulated by ISO requirements. Testing gives the complete picture of compressed air system health, identifies potential sources of contamination, and allows for earlier intervention before potential problems become a compliance or quality issue.

Example: Trace Analytics Report

Only compounds categorized as Oil Vapor (Q>80) will be added to oil vapor results on Trace reports. Possible oil vapors and other compounds are also included on reports to help our customers evaluate their system health from a closer perspective.

Hydrocarbons in compressed air are often a symptom of a deeper problem in the system.

Common sources include:

• Oil-lubricated compressors leaking oil into the air stream.

o Simple hydrocarbons, hexane(C6) through hexadecane (C16)

• “Oil-free” compressors still using lubricants in areas outside the compression chamber: contamination can still occur via seals or worn parts

o This can cause Siloxane contamination.

• Cleaning agents or solvents are also a frequent source of contamination.

o Common hydrocarbons examples are limonene and pinene

By identifying the exact hydrocarbons present, facilities can trace the problem back to a source whether it’s the compressor, the intake, or distribution piping and take corrective action before a failure occurs. Point of Use testing can also help pinpoint the source of contamination before escalation. Trace Analytics is always available to help our customers understand their report results.

Improving Preventative Maintenance

Hydrocarbon testing gives facilities the insight needed to optimize maintenance schedules. Instead of relying solely on time-based or reactive maintenance, hydrocarbons can serve as early indicators of:

• Filter saturation or failure

• Seal degradation

• Leaks in the system

With this data, facilities can perform maintenance targeted to their unique system, reduce downtime, and prevent larger system failures.

Protecting Worker and Consumer Health

Some hydrocarbons found in compressed air such as limonene can cause skin or respiratory irritation. Others may interact with compounds in the air to create harmful byproducts. Identifying potential irritants or toxins early helps protect employees working with compressed air and ensures end users aren’t exposed to contamination. Contamination from compressed air can also work its way to end products. For example, if compressed air is used to pneumatically convey products, the contamination can spread and potentially be harmful. Some oil vapors such as decane, a hydrocarbon found in oil, fuel, and various solvents, is a health hazard to inhale, ingest, and touch.

Comprehensive System Awareness

The Trace Analytics method uses mass spectrometry to compare detected compounds against the National Institute of Standards and Technology (NIST) database, assigning each a “Qual” value that measures the match quality of the compound’s mass spectrum to known standards. This level of detail gives customers the information needed to build risk assessments, monitor changes over time, and evaluate operational changes that might be affecting their system.

Testing for hydrocarbons, or oil vapors in compressed air is an important step to achieving a full picture of a sample. Contamination doesn’t have to be catastrophic and costly. Identifying hydrocarbons in compressed air is a critical part of quality control, system maintenance, and risk mitigation. By using reliable testing methods and reviewing detailed compound identification, customers can gain actionable insight into their compressed air environment. Whether the goal is compliance with ISO standards, protecting sensitive products, or improving the longevity of equipment, hydrocarbon detection is an investment in the reliability of your entire system.