One of the greatest challenges that breweries face is the maintenance of quality. Compressed air and gas contaminants can be detrimental to the beer product and put consumers at risk. A source of potential contaminants that is often overlooked is the compressed air system or the air itself. Compressed air and gas systems play an important role in the brewing process. Contaminants introduced to draft and bottled beer at any stage in the brewing process through production equipment, raw materials, or bottling could all cause off-flavors and odors, oxidation, and spoilage. In addition to compromising the safety of beer, contamination can impact its texture and flavor, leaving customers with an unfavorable product. Compressed air and gas testing for beer products is an essential part of monitoring systems for quality.

Regularly testing your compressed air and gas with an accredited laboratory helps to ensure the consistency of your compressed air system and helps protect the quality of the end-product. Testing can also increase production rates and shelf-life, and prevent customer complaints, boycotts, recalls, or shutdowns.

Compressed Air in the Brewery

Each stage of the brewing process requires clean compressed air so that a high quality final product can be produced that is safe and enjoyable for consumers to drink.

Fermentation

The first use of compressed air begins at the start of production during the fermentation process. Compressed air is used in this stage to increase the oxygen levels in beer, which helps yeast grow and reproduce before they ferment.

Piping and Production

Compressed air also enables beer to flow more quickly through the production line’s piping. Prior to filling and sealing, bottles are cleaned with compressed air and CO2 gets flushed in through the air compressors. Finally, compressed air moves the beer from the keg to the tap, where it’s ready to dispense.

Compressed Pure Gases in the Brewery

Compressed gases are used in many stages in the brewing process. Brewers must monitor gases used to ensure proper gas purity that is contamination-free. Compressed air testing for lines in beer production is the best way to ensure safety and quality. Gaseous contaminants can be found in compressed air and gases that enter through ambient air or within the compressor itself. ISO 8573-6 considers the following as gaseous contaminants to measure:

- Carbon monoxide

- Carbon dioxide

- Sulphur dioxide

- Hydrocarbons

- Oxides of nitrogen

Aeration

This process involves injecting the beer directly with oxygen to produce small air bubbles, which assists in the fermentation process.

Carbonation

Carbon dioxide is added to beer for carbonation purposes, which gives beer its fizzy texture.

Nitrogenation

The addition of nitrogen to beer affects its carbonation quality by producing smaller bubbles. This procedure gives beer a smoother texture, unlike that of traditional CO2.

Contaminants and Microorganisms in the Brewing Environment

Gaseous contaminants can be found in compressed air and gases that enter through ambient air or within the compressor itself. ISO 8573-6 considers the following as gaseous contaminants to measure:

- Carbon monoxide

- Carbon dioxide

- Sulphur dioxide

- Hydrocarbons

- Oxides of nitrogen

Using compressed air that is dry, moisture and oil-free through relevant pressure dew point calculation will ensure that the air is not contaminated with water.

Manufacturers should be aware of particle contamination in their compressor system and microorganisms in the air surrounding the brewing environment. Examples of particle contaminants include metal shavings, glass, plant debris, and rubbers; all of which present danger to customers.

Key microorganisms that can be found in raw materials used to produce the beer include:

- Wild yeast – causes off-flavors, can be harder to detect and control than bacteria

- Lactic acid bacteria – produces diacetyl, which affects the lungs, eyes, nose, throat, and skin

- Pediococcus – P. damnosus, a type of Lactobacilli, produces diacetyl, described as an unpleasant cheesy flavor, a brewery specific organism that develops and settles on the bottom of beer bottles

- Enterobacteriacea – can slow down the rate of fermentation

- Acetic acid bacteria – produces off-flavors when present in high concentrations and may indicate spoilage of the beer

- Obligate anaerobic bacteria – Pectinatus spp and Megasphaera cerevisiae cause beer spoilage in the form of off-smells and off-tastes

Additionally, your air compressor may be drawing microbial contaminants into the system through the intake. The environmental air in breweries is of particular concern due to the presence of circulating microbes. “Environmental factors, such as humidity, temperature, and air speed can have a direct impact on the growth and survival of airborne microorganisms (Crozier-Dodson and Fung, 2002).” A microbial analysis can be conducted in order to fully detect particular microorganisms that can cause beer spoilage.

The Uses of Nitrogen in the Brewery

Nitrogen provides many uses at several different stages in the brewing process. It can be infused into beer during the brewing process using a mixture of 70% nitrogen and 30% carbon dioxide to enhance its taste. Nitrogen can also be used to clean out tanks between batches as it removes wort, mash, or beer to ensure there is no chance of oxidation in the tank. Oxidation can produce a sour taste, which makes nitrogen a good choice for many brewers. Additionally, nitrogen can displace the carbon dioxide in a tank to help move the beer from one tank to the next.

As nitrogen becomes increasingly popular in the brewing industry, the importance of monitoring air and gas becomes even more evident. The mixture of nitrogen that is introduced to beer requires a proper level of purity to ensure the quality and safety of the final product.

Where Does Contamination Originate?

Beer is susceptible to various compressed air and gas contaminants at each point in the production process.

- Compressor system – the compressor lubricant may produce oil aerosols, and rust particles are able to break free from the piping

- Brewing environment – dust particles, hydro-carbons, and humidity collect in the environment and are concentrated from the air compressor

- Brewing plant – surfaces that come into contact with wort, beer, or yeast must be sterilized and cleaned to prevent microbial contamination, which could be sucked into the compressed air system through the intake

- Packaging – secondary contamination from ambient air can be introduced through the compressor intake

- Malt – potential release of mycotoxins (Aflatoxin B1, ochratoxin A, zearalenone, deoxynivalenol (DON) and fumosins B1 and B2) can be transmitted from contaminated grains into beer through the compressor intake. Mycotoxins can cause harm to humans and affect fermentation due to their impact on yeast

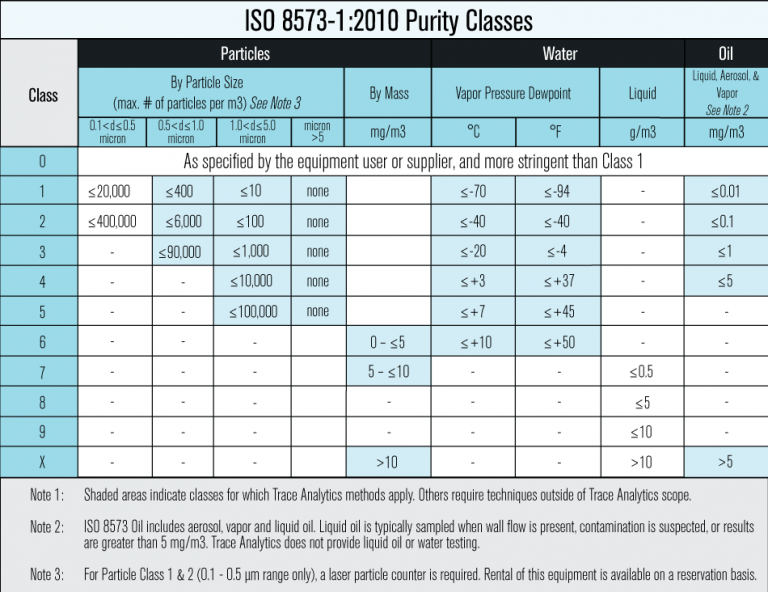

ISO 8573-1:2010 Purity Classes

Brewers can use ISO 8573-1:2010 to find purity classes for testing the following contaminants in their compressed air:

- Particles (pipe scale, wear particles, atmospheric dirt)

- Water (liquid, vapor, and aerosol)

- Oil (liquid, vapor, and aerosol)

ISO 8573-1:2010 is the international standard for compressed air quality and consists of nine parts that provide limits to test to. Testing limits are determined by a risk assessment which accounts for the compressor system filtration, dryers and point-of-use filters. The chart below can be used to determine which section of ISO 8573 to follow according to what contaminants are being tested for.

ISO 8573-1

Outlines contaminants and purity classes in regards to particles, water, and oil, in addition to identifying gaseous contaminants. It is important that these contaminants are prevented from entering the compressor system as each can be detrimental to the quality of beer. Regular compressed air testing helps determine that beer makers’ systems are functioning as expected.

ISO 8573-2

Outlines testing methods for oil in the form of aerosols and liquid that are present in compressed air. Oil-free air is necessary for brewing so it does not kill the essential yeast and cause the froth on top of the beer to flatten.

ISO 8573-3

Provides the sampling method for measuring water in the form of pressure dew point or humidity in compressed air. Humidity found in a compressed air system can derive from water vapor moisture introduced from ambient air and can be due to the lack of a desiccant dryer. It is necessary that this water does not come in contact with the compressed air, as it can cause corrosion in piping and contaminate the final product.

ISO 8573-4

Provides the sampling method for measuring contaminants in the form of solid particles that be found in compressed air with regards to size and concentration. Particles can include debris in the form of metal shavings, glass, rubbers, insect parts, liquid water, and viable microorganisms; all of which pose a dangerous threat to consumers.

ISO 8573-5

Outlines testing methods for oil vapor and organic solvents in compressed air, which can compromise the taste of beer if leaked from the compressor.

ISO 8573-6

Outlines testing methods for gaseous contaminants. Gases such as carbon dioxide and carbon monoxide used in brewing must be measured for adding the proper amount of carbonation to the beer. Over-carbonation will produce excessive foam, while not enough of it will produce flat beer.

ISO 8573-7

Outlines testing methods for viable microbiological contaminants in compressed air. Organisms such as yeast, bacteria, and mold can be distinguished using this standard so that beer is safe to drink and retains its quality.

ISO 8573-8

Outlines testing methods for measuring solid particle content in compressed air by mass concentration.

ISO 8573-9

Outlines testing methods for liquid water content in compressed air. Water found in compressed air can be detrimental to beer due to the potential of oxidation in the compressor.

Compressed Air & Gas Testing for Beer Products

It is necessary for manufacturers to test their compressed air and gas regularly in order to maintain the quality, safety, and consistency of beer for customers. Dryers and filters protect products against contamination. They should be used in conjunction with compressed air testing to help ensure safety. When testing for viable particles, oil, water, and microorganisms, breweries can adhere to ISO 8573: 1-9 standards for guidance.

Brewers are required to comply with the Food and Drug Administration (FDA) by setting an active Good Manufacturing Practice (GMP) plan in place. “Today, modern brewing plants perform myriad analyses on their beers for quality control purposes . . . Samples are pulled at almost every step and tested for oxygen content, microbial infections and other beer-aging compounds” (Obi 2018). A GMP plan is comprised of “record keeping, personnel qualifications, sanitation, cleanliness, equipment verification, process validation, and complaint handling” (ISPE). GMP requirements are open-ended, which enable manufacturers to apply the appropriate measures according to their facility’s unique needs.

Regular compressed air and gas testing will help breweries achieve compliance with the FDA and provide customers with a safe product for consumption.

Testing with Trace Analytics, LLC

Trace Analytics provides a selection of compressed air analysis packages and can test to a variety of standards such as ISO 8573 and other custom specifications for the analysis of particles, water, oil, gas, and micro. Our accredited laboratory delivers quick, reliable results that can ensure your compressed air is contamination-free and meets the standards required of beverage manufacturers. Breweries can be confident that their products are of high-quality, safe for consumption, and that they ensure brand reputation.

Refereneces:

“Brewery Contaminants, Challenges and Remedies – A Review.” The Journal of Microbiology, October 2018, Michael Okpara University of Agriculture, Umudike

Compressed Air in Breweries. Lars Larson and Inge Russell. 2006.

“Food and Beverage Air Compressors.” Quincy Compressor, 2019,

Food & Beverage

“Foreword.” ISO 8573-1:2010(en), ISO, 2019,

https://www.iso.org/obp/ui/#iso:std:iso:8573:-1:ed-3:v1:en

“High quality compressed air for the beverage and bottling industries.” Parker Hannifin, 2011,

“How Home Breweries and Independent Beer Companies Are Using Compressed Air.” Quincy Compressor, Quincy Blog, 2019,

How Home Breweries and Independent Beer Companies Are Using Compressed Air

Larson, L., Russell, I., & Liedl, R. (2006). Compressed air in breweries. St. Paul, MN: Master Brewers Association of the Americas.

“The Advantages of Onsite Nitrogen Generation for Brewers.” Compressed Air Best Practices, 2019,

https://www.airbestpractices.com/industries/food/advantages-onsite-nitrogen-generation-brewers

“The basic principles behind the detection of infections by considering unwelcome wild yeasts.” MoreBeer! MoreBeer! Articles, 2019,

https://www.morebeer.com/articles/Wild_Yeast_Detection_Remediation

“Using ISO 8573-1 to Test Compressed Air: Clearing the Confusion.” Compressed Air Best Practices, 2019,

https://www.airbestpractices.com/industries/food/using-iso-8573-1-test-compressed-air-clearing-confusion